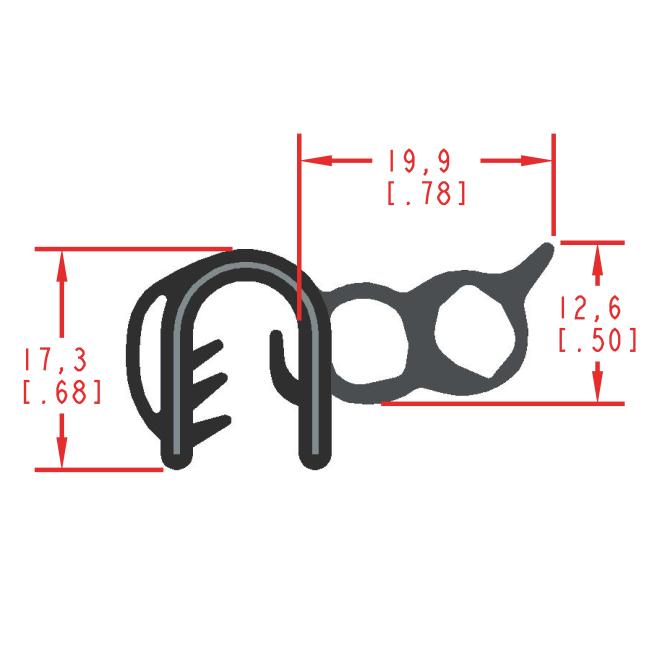

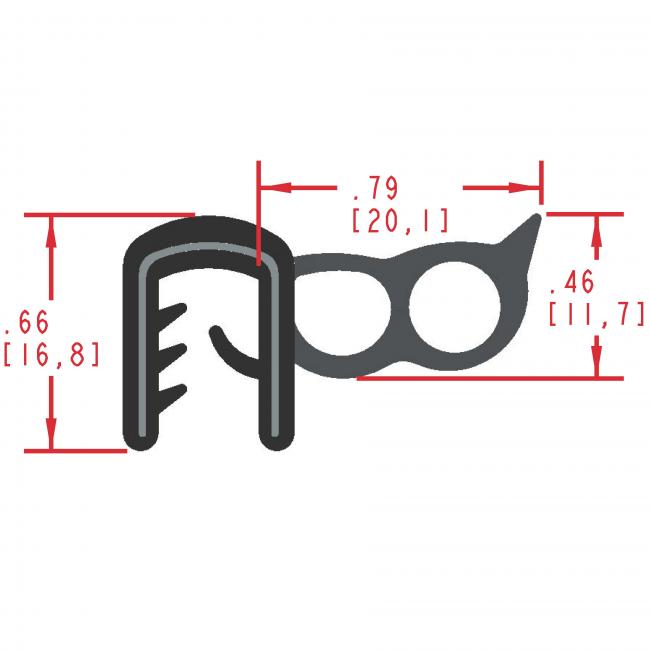

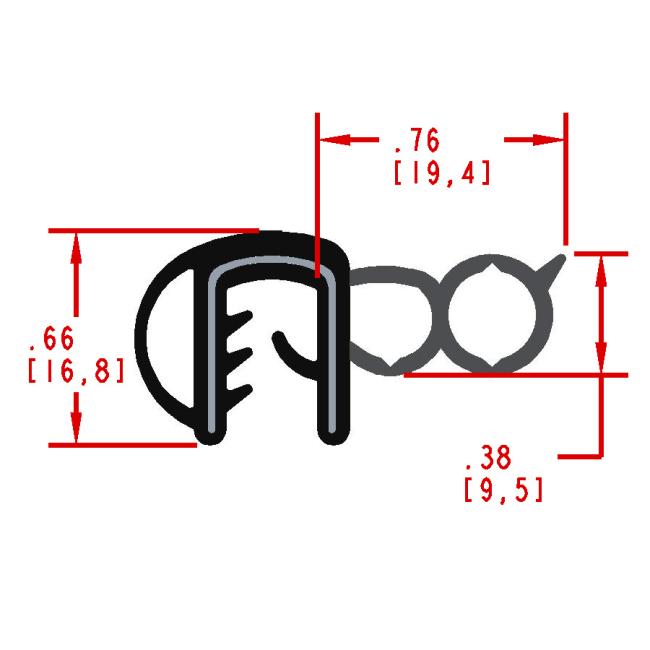

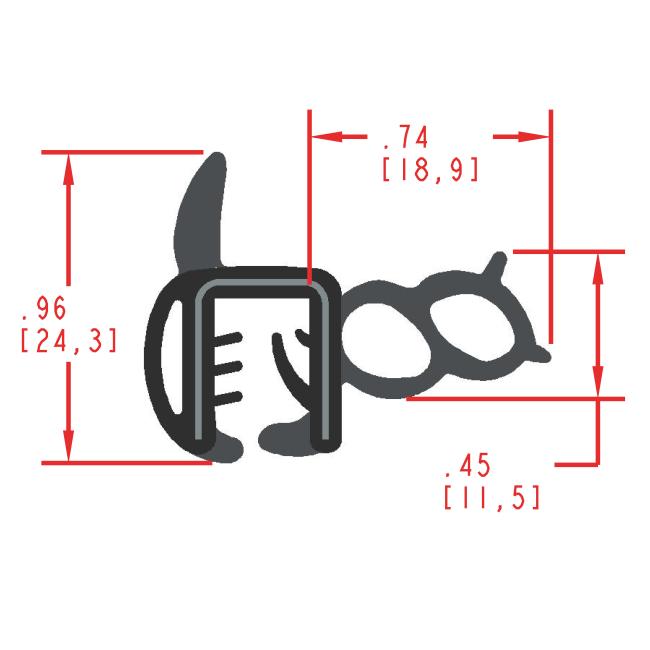

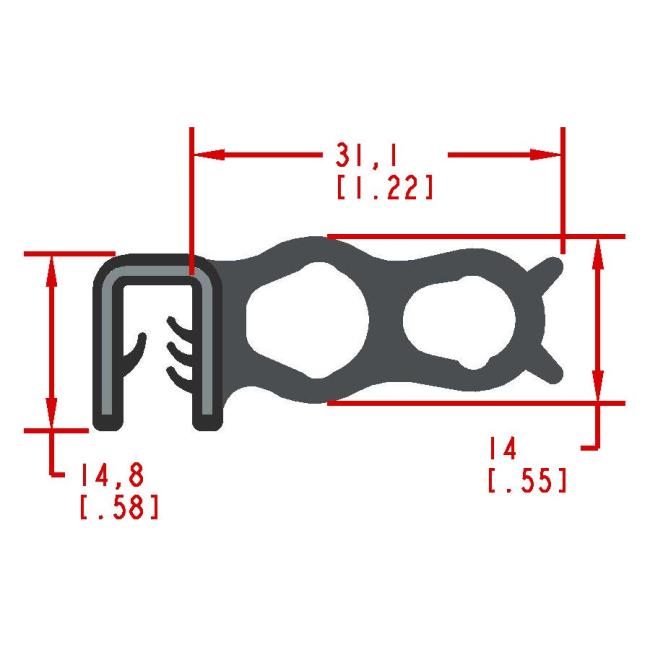

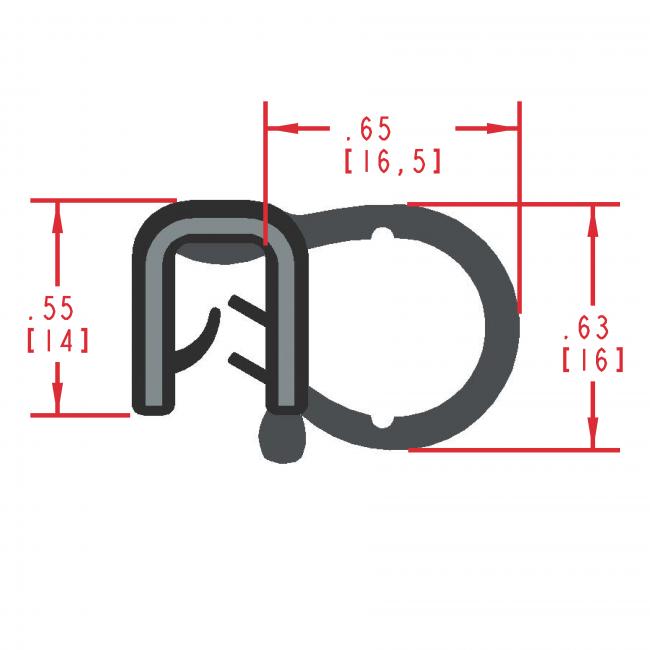

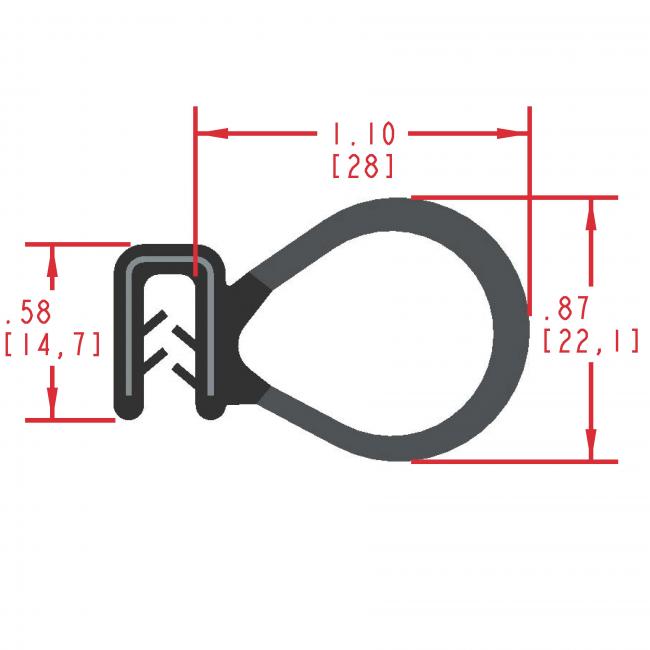

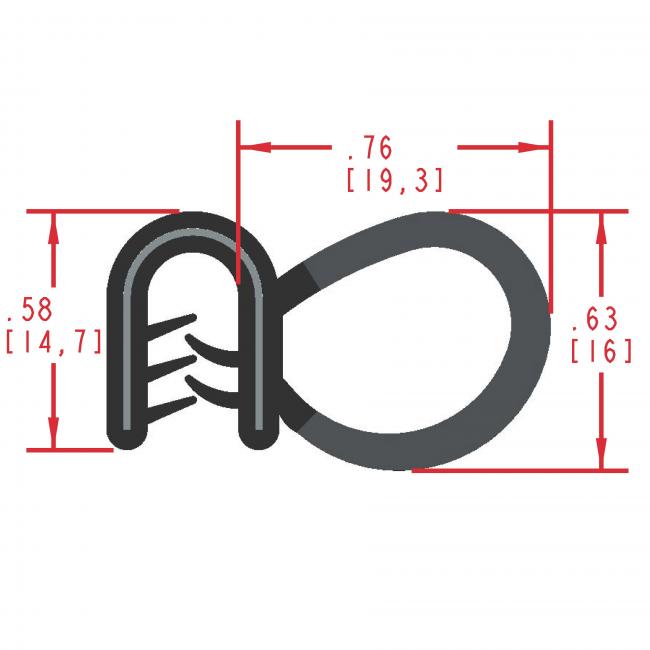

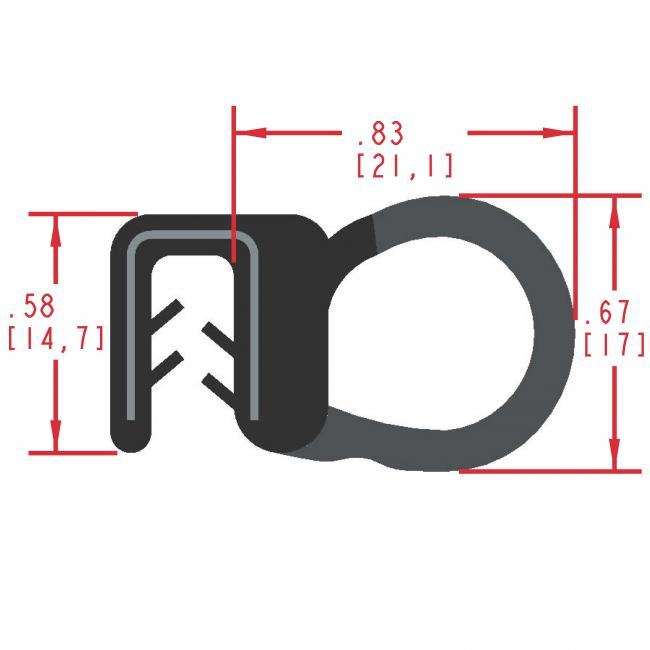

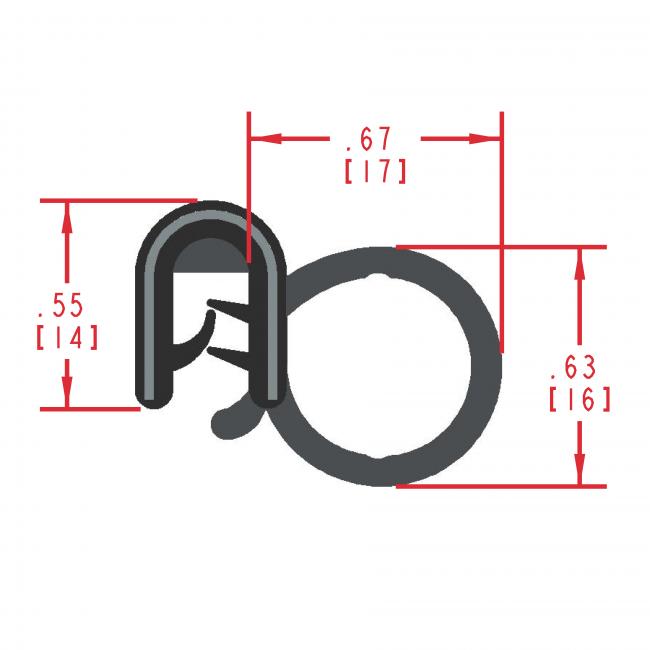

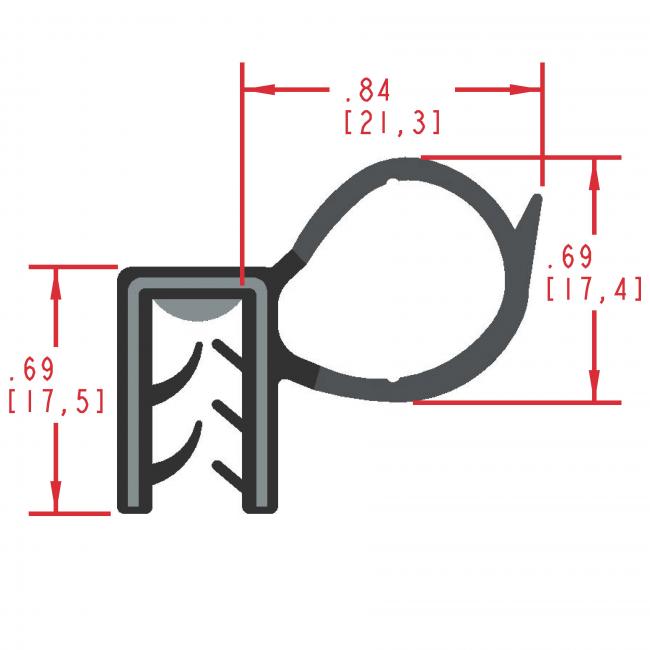

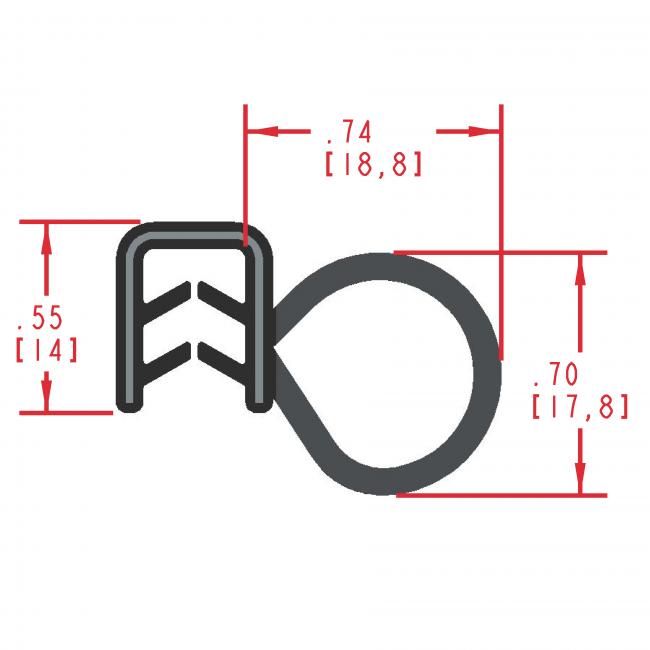

Side Bulb Seals

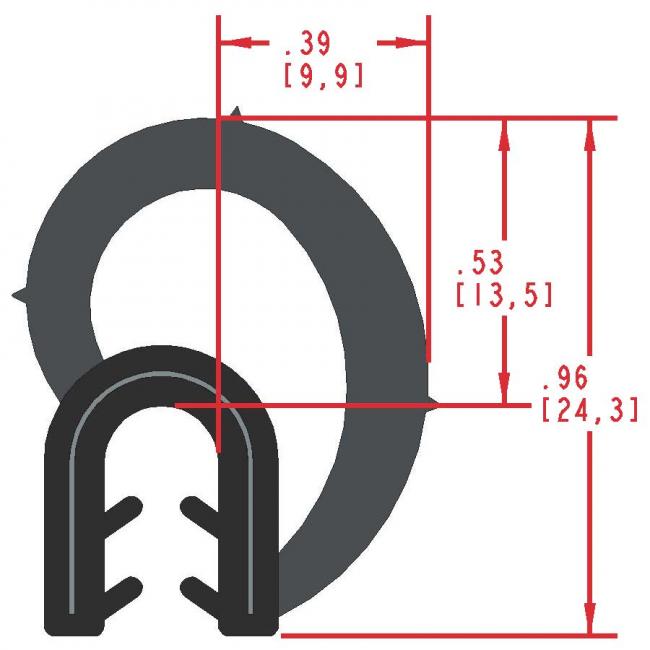

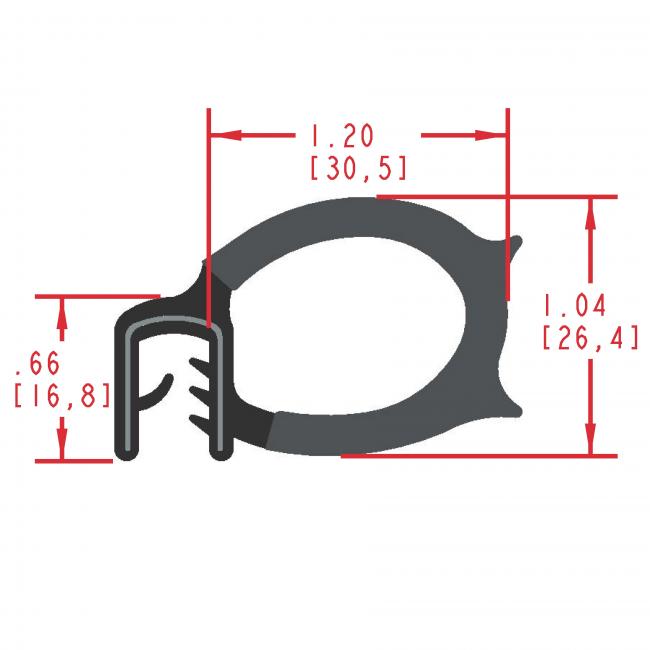

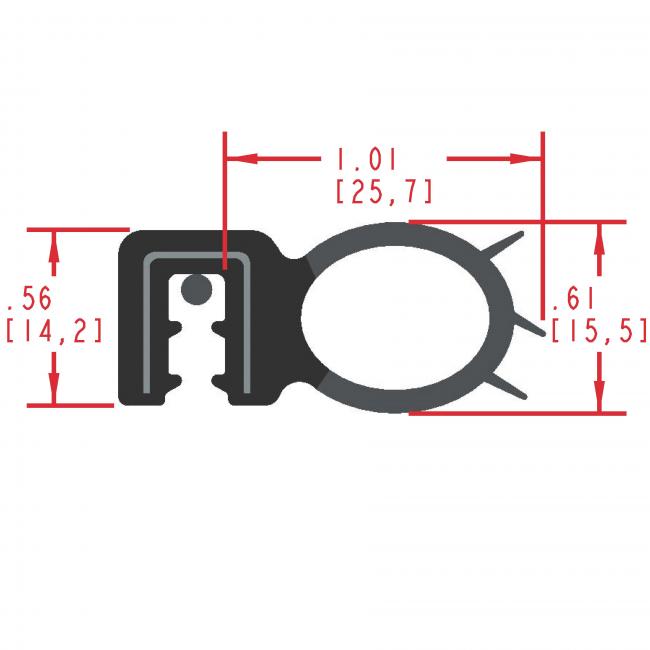

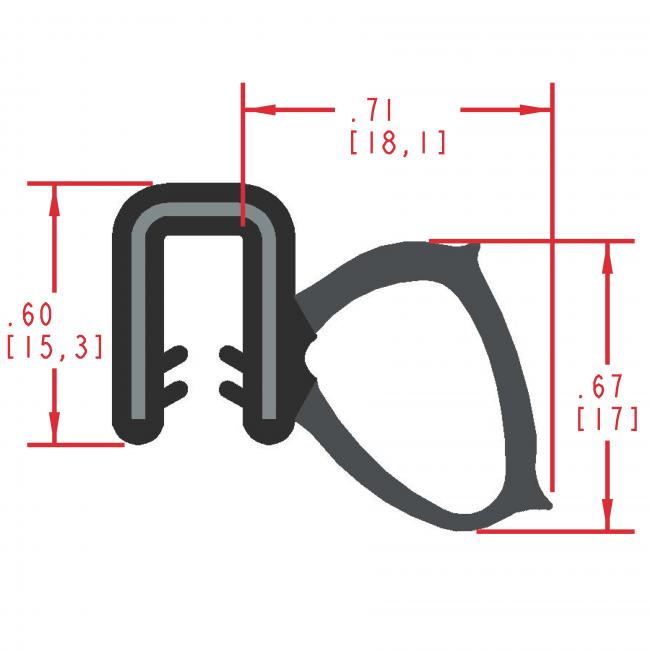

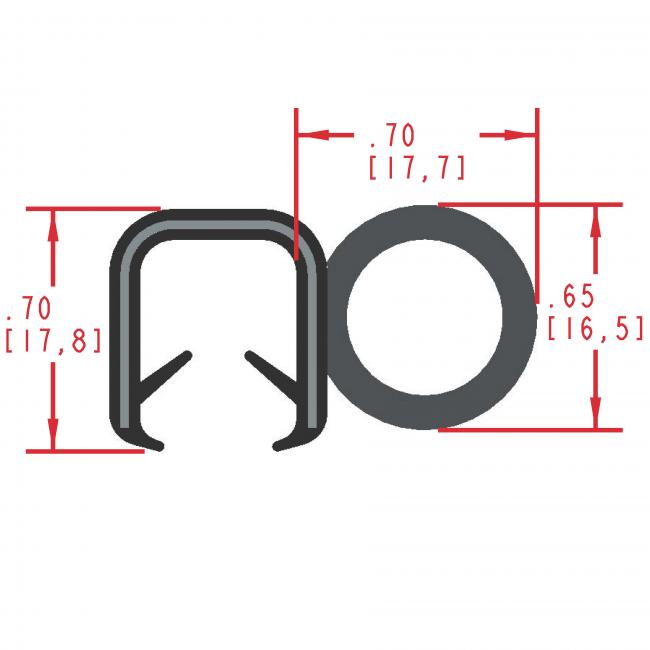

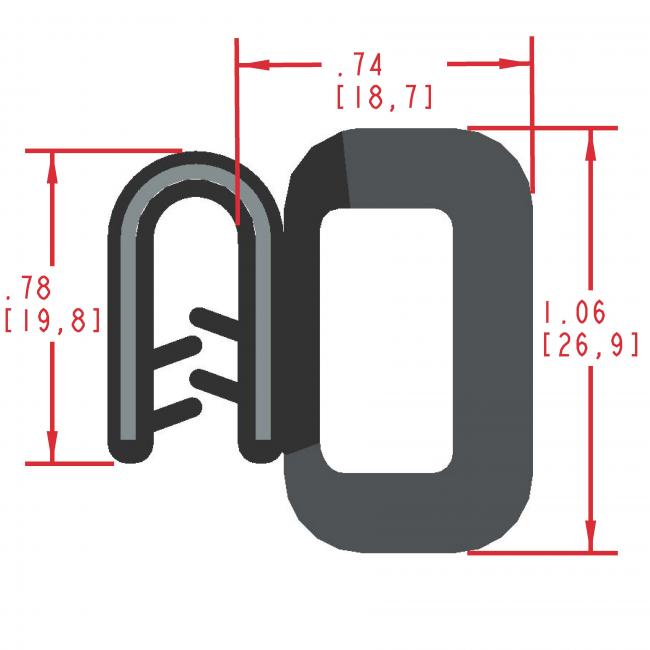

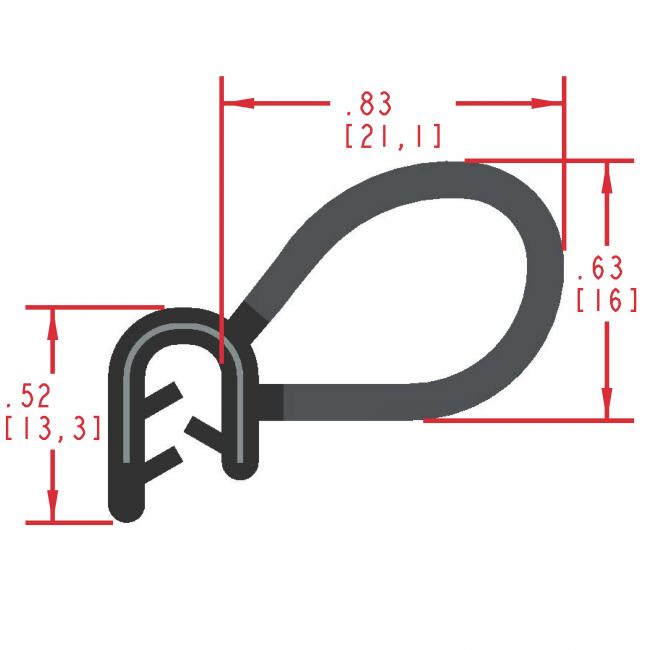

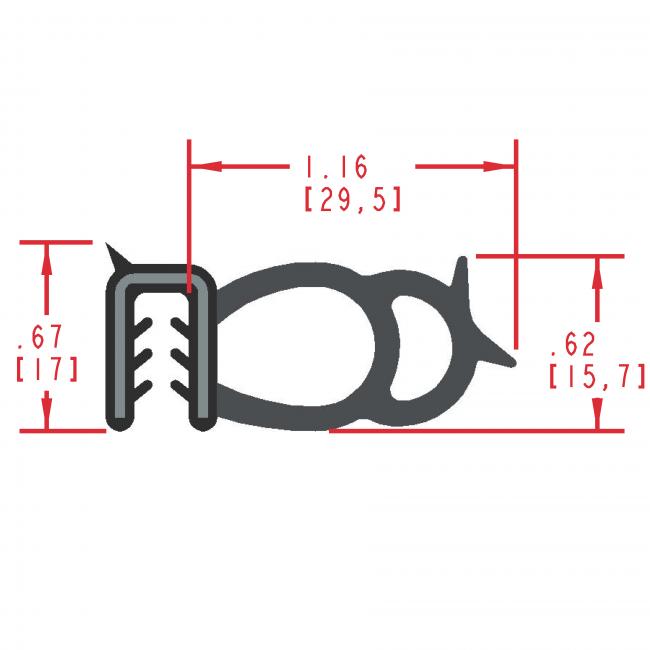

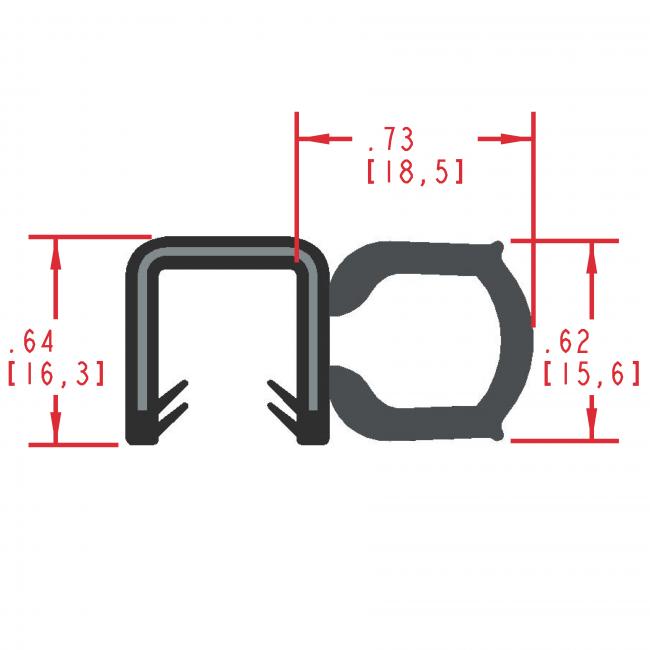

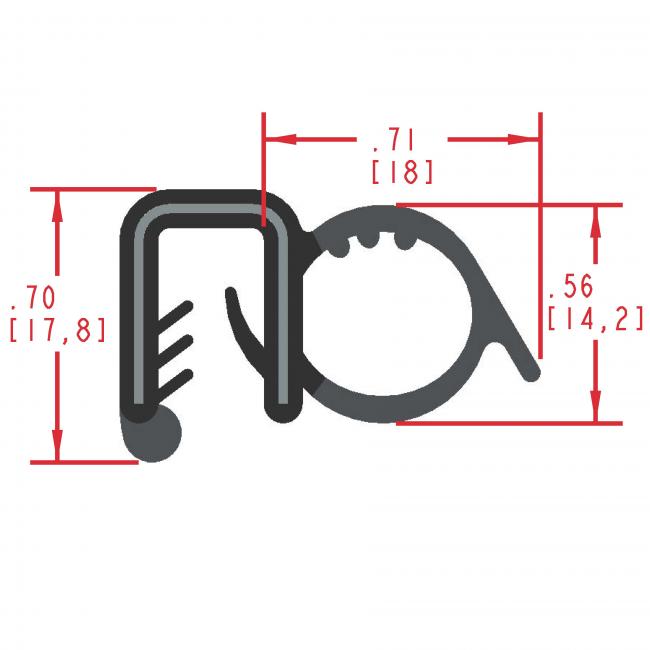

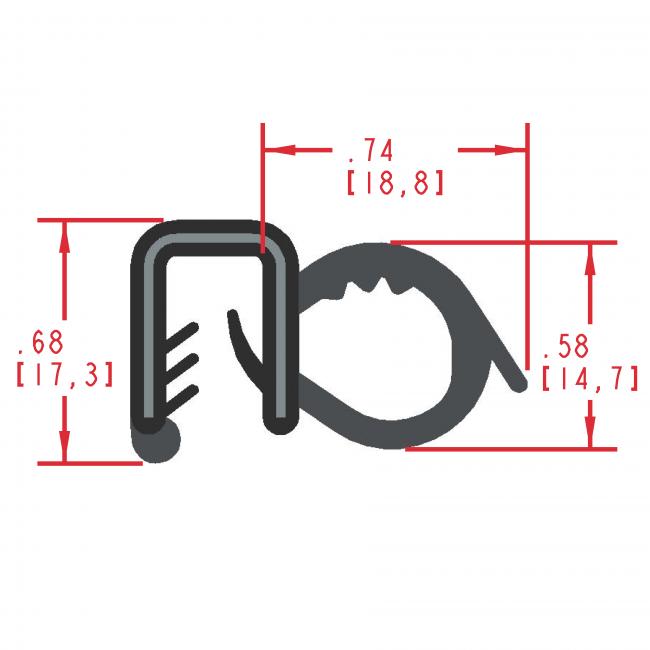

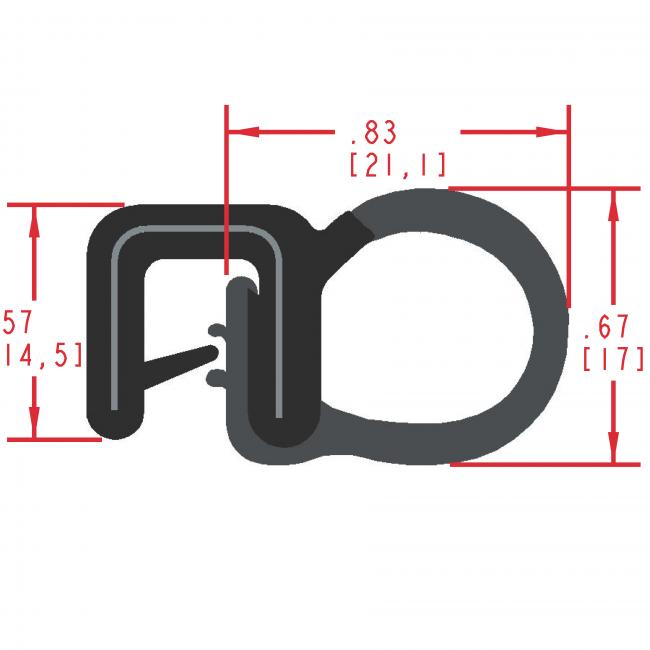

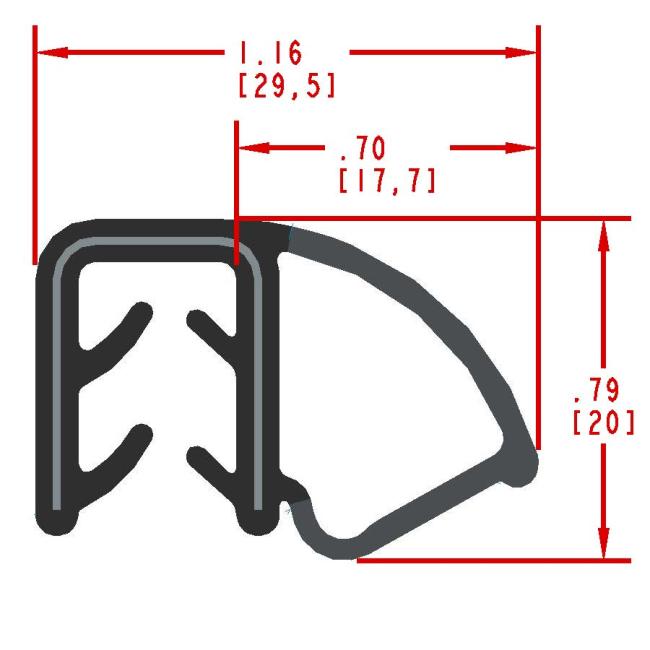

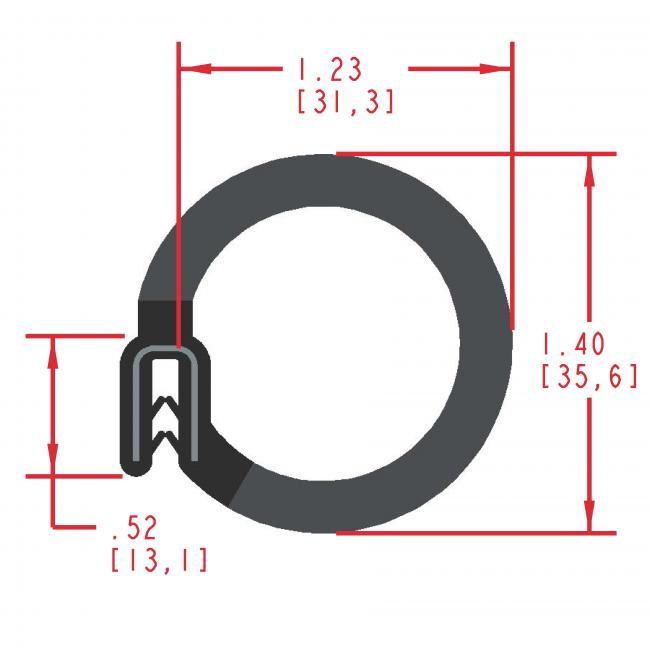

Ebco’s side bulb seals are very similar to the top bulb seals that we stock. It has all the same jobs as the top bulb seal, such as preventing debris, weathering, and noise from entering an opening. The main difference between the two is in the name: instead of the bulb being on top, the bulb is extruded on the side of the edge trim. The metal carrier provides the attachment grip and the bulb fills the gap. The bulb allows for some movement or gap variation while maintaining a tight seal. Bulb geometry can be varied to get the desired bulb compression or door closing force.

Side bulb seals come with a metal carrier for installation. We also offer this sealing style without the metal carrier in our extruded dense and extruded sponge seal collections.

We hold ourselves to the highest standards when it comes to producing our products and we ensure that our seals are made with the highest grade EPDM in the market. This provides safety and efficiency on the job site or wherever it’s needed. The plate thickness that the rubber bulb seals can be applied on ranges from 0.024 inches to 0.371 inches, and we are always adding to our inventory. Our wide selection of side bulb seals can be utilized in virtually every situation. We have a dozen different designs to choose from but in case none of these options work for you, we have the capability to customize our seals for what you require. Don’t hesitate to contact us!

If you need something to guarantee maximum strength, we provide the following applications: adding vent holes, adding adhesive in the rubber U channel trim, slip coating, and molded or spliced joints.

Features and Benefits

- High-quality materials and manufacture.

- Easy installation with flexible seals.

- It prohibits dust and noise.

- Cost-efficient.

- Additional applications to secure extra strength.

- Customizable for when you need it.

Side Bulb Seal Technical Support

Are you looking to get a customized side bulb seal profile? Our team of engineers can help with any and all technical assistance! Options for technical assistance include Compounding Services, Material Testing, Physical Testing, and Simulation Testing. Each of these services can be tailored to meet your requirements at any part of the design cycle. Once we fully evaluate your application, we will recommend the seal profile appropriate for your design.

Call Us To Get Started: 847-531-9500